Corrugated Drainage Pipe for Water Conveyance

At Colonial Construction Materials you will find several options for drainage pipe including high density polyethylene (HDPE pipe), corrugated metal pipe (CMP) and steel-reinforced polyethylene pipe (SRPE).

Types of Drainage Pipe

Discover More Drainage Solutions

HDPE Fittings for Drainage Pipe

Single Wall and Double Wall Fittings

Connect corrugated pipe with HDPE Fittings including Tees, Wyes, Couplers and Flared End Sections. Choose from Single Wall, Double Wall or Injection Molded Fittings.

Drainage Pipe for French Drains

Gravel Free French Drain Solution

NDS’s EZ-Flow Pipe features an HDPE corrugated pipe surrounded by poly-rock and mesh. This gravel-free French Drain is lightweight and easy to install.

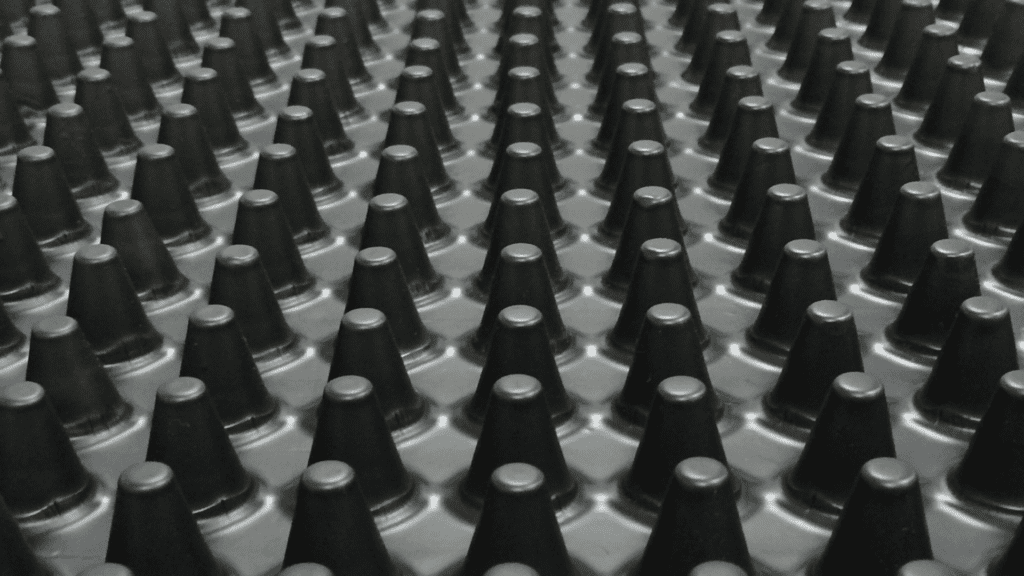

Detention and Filtration Systems

Underground stormwater systems

Below surface stormwater systems filter and store stormwater runoff without sacrificing land or aesthetics. Learn more about our chamber systems, modular and large diameter pipe systems.

Explore More Stormwater Solutions

Need a price on pipe?

Contact our sales team to get started.