Largest Solar Facility East of the Rockies

Project Details

Sector:

Energy

Location:

Spotsylvania, VA

EPC:

Mortenson

Sub-Contractor Partners:

The Erosion Company

L&S Site Contractor

AACME Hydroseeding

Eco-Express

Top Gun Enterprises, LLC

Monarch Vegetation

Brent Scarbrough & Co, Inc.

Size:

617 MW | 6,350 acres

About Spotsylvania Solar Farm

The Spotsylvania Solar Energy Center is the largest solar project east of the Rockies.* The 617 MW solar farm encompasses approximately 6,350 acres of land including 3,500 developed acres and 2,000 acres of preserved land.

Spotsylvania Solar is comprised of four separate solar projects: Pleinmont 1, Pleinmont 2, Richmond Solar and Highlander Solar. Despite its size, Spotsylvania Solar is almost invisible to the naked eye because it is surrounded by forest cover. The solar facility has all single axis tracking solar panels that follow the sun for maximum solar output. The solar power generated by Spotsylvania Solar is estimated to power 111,000 homes at peak output and offset 340,000 tons of carbon dioxide emissions each year.

Microsoft purchased 315 MW of solar energy from Pleinmont 1 and Pleinmont 2. The energy output from these two Virginia solar farms enables Microsoft to make a significant step towards its clean energy goals. At the time of purchase, this represented the single largest corporate purchase of solar energy.

Before the site was developed into the Spotsylvania Solar Energy Center, the land was used for logging and timbering. The Virginia State Corporation Commission approved the massive solar project in 2018 and construction began in 2019. All four solar projects are active and construction is estimated to finish by mid-2023.

*as of publication in January 2023.

Project Development Benefits

Four Projects in One

Pleinmont 1: 99.6 MW, completed in 2020

Pleinmont 2: 293.9 MW, currently active

Richmond Solar: 24.2 MW, completed in 2020

Highlander Solar: 200.2 MW, completed in 2020

Microsoft purchased 315 MW of solar energy from Pleinmont 1 and Pleinmont 2. The energy output from these two Virginia solar farms enables Microsoft to make a significant step towards its clean energy goals. At the time of purchase, this represented the single largest corporate purchase of solar energy.

Before the site was developed into the Spotsylvania Solar Energy Center, the land was used for logging and timbering. The Virginia State Corporation Commission approved the massive solar project in 2018 and construction began in 2019. All four solar projects are active and construction is estimated to finish by mid-2023.

*as of publication in January 2023.

Project Development Benefits

Four Projects in One

Pleinmont 1: 99.6 MW, completed in 2020

Pleinmont 2: 293.9 MW, currently active

Richmond Solar: 24.2 MW, completed in 2020

Highlander Solar: 200.2 MW, completed in 2020

“Working in Virginia, we knew managing our erosion control and vegetation was critical to the success of the Spotsylvania Solar project. At over 3,000 acres of cleared land, we needed someone who would be able to keep up with the demand of BMPs we would need to stop erosion and achieve vegetation growth. Colonial Construction Materials was integral to the project as they provided large BMP deliveries multiple times per week. They were able to source difficult to find geotextiles and seed mixes, maintain solid inventory and provide us extensive customer support even through the pandemic. I would recommend working with CCM for any project big or small if you want a dependable and knowledgeable source of materials for your project.”

Emily Raymond

Assistant Superintendent

Mortenson

Our Role During Construction

Our team at Colonial Construction Materials supplied Mortenson (EPC) and many sub-contractors with erosion control and geosynthetic solutions throughout the construction of Spotsylvania Solar. Through material supply and design assistance, Colonial Construction Materials, led by Pat Branin, supported the careful development of thousands of acres of land in northern Virginia.

High Volume Supplier for EPC and Sub-Contractors

During peak construction activity our trucks made daily deliveries to the Spotsylvania Solar Farm site in order to meet project deadlines and solve soil challenges.

Over the course of construction, our team supplied approximately:

“Pat and his team at Colonial Construction Materials were a tremendous supplier for our solar project in Spotsylvania over the last 3 years. They supported our site with BMPs, seeding mixes, geotextiles, drain tile, product samples, and even product demonstrations to help us further prevent and mitigate erosional issues on our 3500 acre solar site with 388 sediment basins. This site called for numerous, highly specific BMP’s to be installed and construction always moved at a very rapid pace. Colonial continued to supply us with all necessary materials and keep up with our busy schedule without issue. The site also had very specific restrictions, including extremely strict delivery times. Colonial Construction Materials helped us adhere to these restrictions and continually delivered multiple truckloads of materials a day to support both Mortenson, as well as our civil and seeding subcontractors. Once again, we cannot thank CCM enough for their dedication to serve and supply our project over the last several years and look forward to the chance to work with them again in the future.”

John Garceau

Assistant Superintendent, Solar and Renewables

Mortenson

Project Challenges

Solar development presents unique construction challenges.

According to Mortenson, some of those challenges included the construction of hundreds of retention ponds, overcoming terrain and the challenging Virginia weather.

In addition to environmental challenges, Spotsylvania Solar was in the midst of development when the COVID-19 pandemic began in 2020. Because the state of Virginia qualified the construction industry as an essential business, construction of Spotsylvania Solar was allowed to continue. However, like so many projects during the pandemic years, the crippled supply chain forced contractors on-site to continuously adapt timelines and product selection.

Retention Pond Construction

Spotsylvania Solar was developed on approximately 3,500 acres of land. In order to meet Virginia stormwater regulations, the site required of hundreds of retention ponds that would collect and retain stormwater runoff.

An extensive network of ditches conveyed runoff to the 388 stormwater ponds. As the ditches and ponds were graded and constructed, Mortenson proactively installed erosion control blankets to any slopes greater than 3:1. Installing erosion blankets during pond and ditch construction is not standard practice on most sites. However, because of the size of Spotsylvania Solar Farm and the scale of land development, Mortenson took proactive action to protect slopes during and after pond construction in order to mitigate soil erosion.

An assortment of erosion blankets were installed but many slopes were lined with Straw Coconut blanket. This double-net blanket offers superior erosion protection than Single Net Straw Blanket because of the coconut fibers and two nets.

One pond located at the back of the site presented particularly difficult challenges for erosion control. A gradual slope covering approximately 23 acres leads towards the back of the project. At the bottom of the site, the gradual incline steepens to a 2:1 slope that terminates at the stormwater pond.

Runoff flows down the gradual incline and then gains velocity when it reaches the 2:1 slope. This slope was regularly subjected to high concentrated flow that was further exacerbated by a neighboring access road.

The concentrated flow was severely eroding the slope, creating rills and threatening the stability of the structure. Multiple erosion control products including Turf Reinforcement Mats and articulated concrete block mats failed because they could not support the volume and velocity of water.

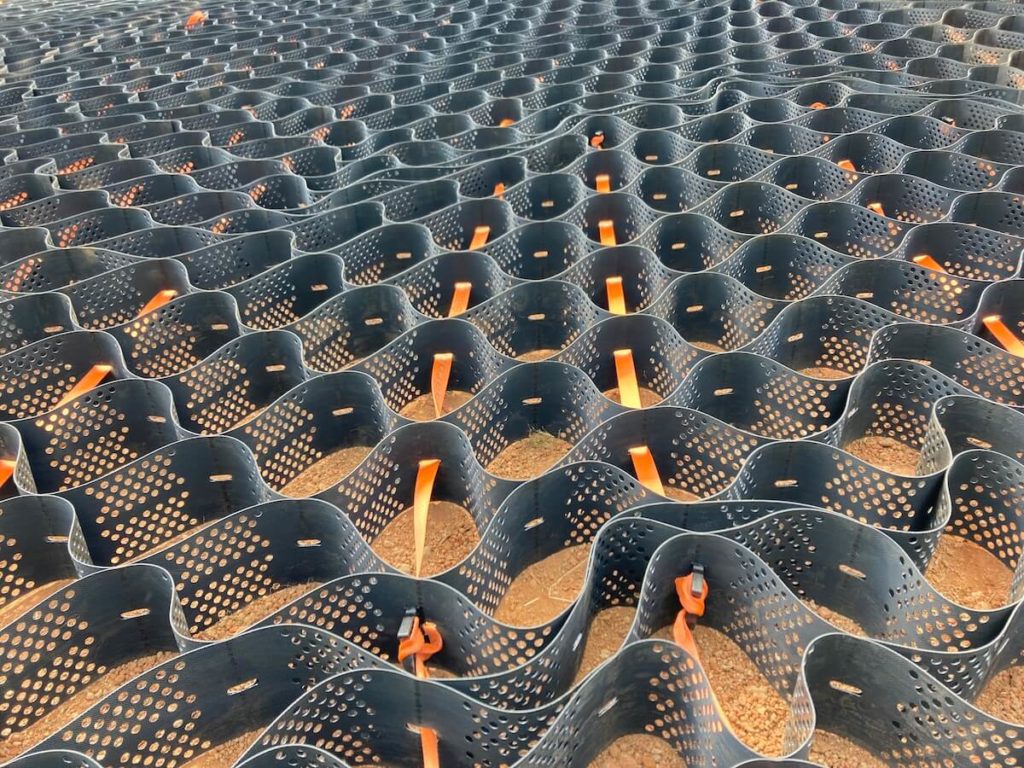

The Solution: GEOWEB Geocell Slope Protection System

After the previous products failed, Pat made a visit to the site to inspect the slope. The critical reason the products were failing was because fast-flowing water was getting under the material.

The solution Pat suggested was the GEOWEB® Slope Protection System. GEOWEB® geocell created structural support on the slope that was not achievable with erosion control blankets or turf reinforcement mats.

The cellular confinement system has perforated cells which allows water to infiltrate vertically and flow horizontally while holding soil in place and preventing soil loss.

2,760 square feet of GEOWEB GW30V6 (mid-size cell, 6-inch depth) was installed over the 2:1 slope using TP-225 tendons and ATRA® Tendon Clips. The tendons were tied to a buried deadman pipe and secured to the geocell system with ATRA® Tendon Clips that provide twice the pull-through strength of alternative load transfer devices.

The GEOWEB® system was filled with on-site fill which is a significant cost-saving factor for solar sites and an advantage for projects that do not allow imported fill.

After installation, the slope was hydroseeded and covered with a Straw Coconut Erosion Control Blanket for additional protection.

Stabilizing Soft Soils

Another construction challenge was stabilizing soft soil for access road construction.

In many cases, access roads for large construction sites can be stabilized with woven geotextile fabric or heavy-weight nonwoven geotextiles. At Spotsylvania Solar Farm, several roads required a higher performance geotextile because the subgrade before the stream crossings was so wet and soft. Mortenson chose a composite geogrid for these high risk areas. The composite geogrid includes a nonwoven geotextile fabric laminated to a bi-axial geogrid. The all-in-one geosynthetic was the right choice for stabilizing these access roads because it effectively confined stones, separated fines while providing soil stability without the need for layers of geotextiles.